Supply Chain Services

Our Approach: Right Parts, Right Time, Right Quantity in the Most Cost-Effective Way

Our same industry-leading supply chain that supports the NovaSource core O&M business is now available for your self-performing or 3rd party O&M needs.

Sourcing, Procurement, & Supplier Management

- Direct OEM relationships, 400+ vendors, 1,000+ buys per week

- Support for EPC / Initial Procurement and Replenishment

- Part refurbishments and Contact Manufacturing

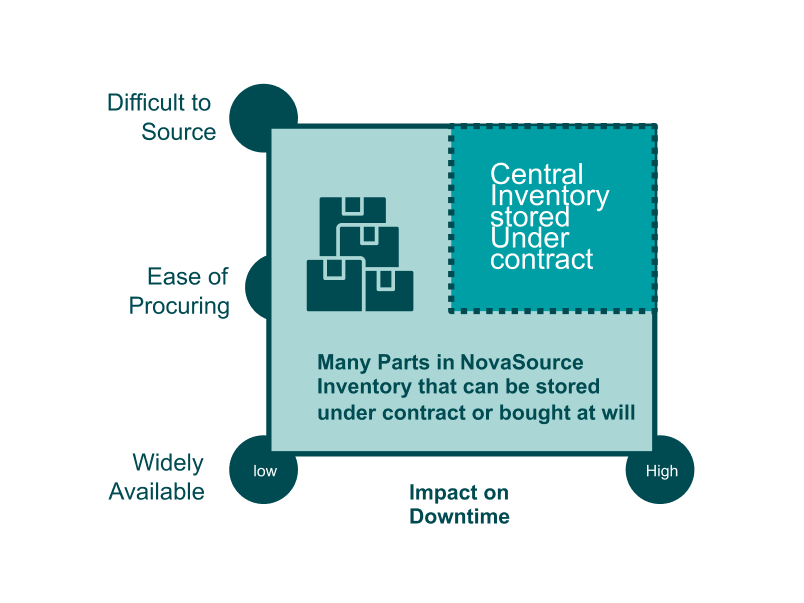

Inventory & Spares Planning

- Demand-based planning and auto-replenishment, don’t let a part leave you offline

- $10 million+ parts in inventory

Warehousing & Logistics

- 15+ Forward staging warehouse, 1 large Central Distribution Warehouse

- Part Criticality based ship out commitments (24hr for most critical parts)

Three components of a robust O&M program:

- Data-driven maintenance schedule

- Capital investments in critical spare parts

- Efficient and intelligent inventory management + spare parts replenishment and supplier processes

Optimizing Profitability with Intelligent Supply Chains and Robust O&M

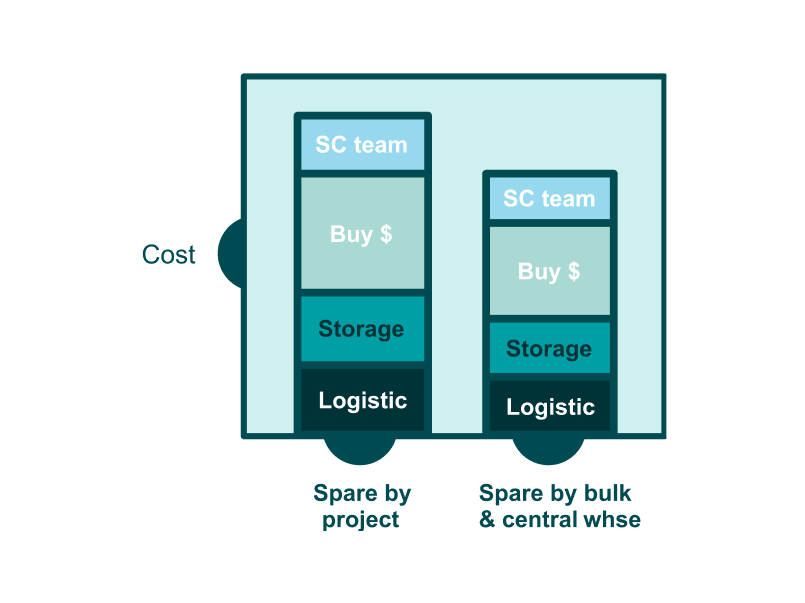

Historically, wind and solar energy have managed inventory of spare parts on-site, creating some non-intentional redundancies in inventory.

NovaSource utilizes a centralized, automated inventory and replenishment system that results in:

- Easier, more effective management and scaling of spare parts quality

- Maximized economies of scale

- Reduced overhead costs

- Better overall O&M experiences

- Increased profitability

With centralized inventory, asset managers can buy in bulk, reduce transport costs and redundancies in inventory, all while having better inventory control and replenishment planning. Shipping parts from inventory when work is scheduled or emergency need arises makes O&M operations linear.

NovaSource offers this differentiated service and continues to invest and build an industry- leading supply chain function to help drive this methodology throughout the market.

Intelligent Supply Chain, by the Numbers

Professional

- +25 Professionals

- Procurement, Spare Parts, Inventory / Warehousing, Logistics

400+ vendors

- 1,000+ Buys per week

- 40+ RMAs per month

16+ Storage locations

- Central Inventory in the US, Chile, and EMEA

>$10M+ of Inventory on hand

- +500 SKUs managed and replenished

Specialty Capabilities

- Contract Mfr. & Use based Replenishment System

Subcontracts Capabilities

NovaSource aims to self-perform the key ancillary services needed in the market today. We have dedicated staff that oversee and manage a large base of subcontract specialist companies to tap on for various services and specialized equipment as needed to fulfill total asset management needs:

- Logistics Services

- Crane & Rigging

- Emergency GSU Equipment (Degasification Rigs)

- Overhead Collection Line and Equipment Repairs

- Road Maintenance / Heavy Equipment land remediation efforts at site

- Solar Module Cleaning

- Vegetation Management